steel pipe making machines

steel pipe making machines

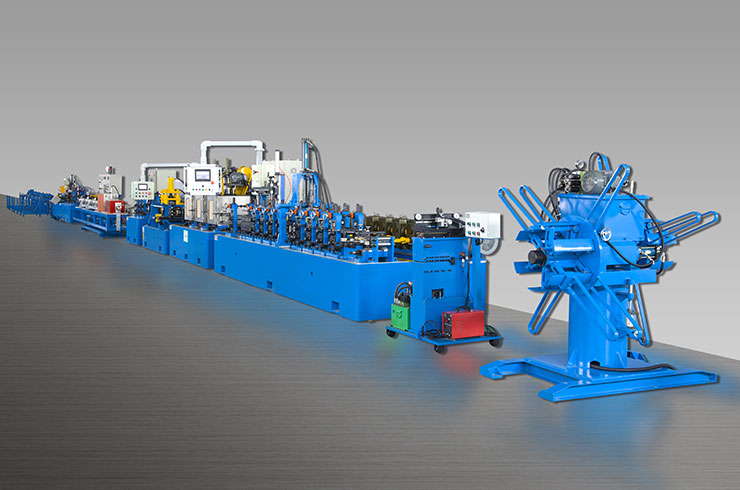

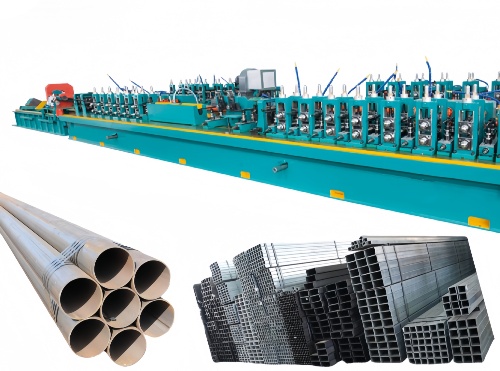

This Production Line Adopts W Molding, Welding the Industrial Welded Pipe Required by Customers by Single Cathode Electric Magnetic Control Welding, and Using Different Roll Moulds to Produce Pipes of Different Specifications. The Production Line Can Produce: Titanium Tube, Sanitary Fluid Pipe, Heat Exchanger Pipe, Stainless Steel Water Pipe and Other Industrial Pipes. Application Scope:

Automotive: Exterior Parts, Hot Parts

Kitchen Equipment: Sink, Gas Stove, Refrigerator

Steel Pipe: Structural Pipe and Row Pipe

Chemical Equipment: Heat Exchanger Tube, Chemical Industrial Stove

Transportation Equipment:! Containers, Railway Vehicles

Electrical Appliances: Washing Machine, Dryer, Microwave Oven, Etc.

Features of High-Speed Precision Welded Pipe Production Line:

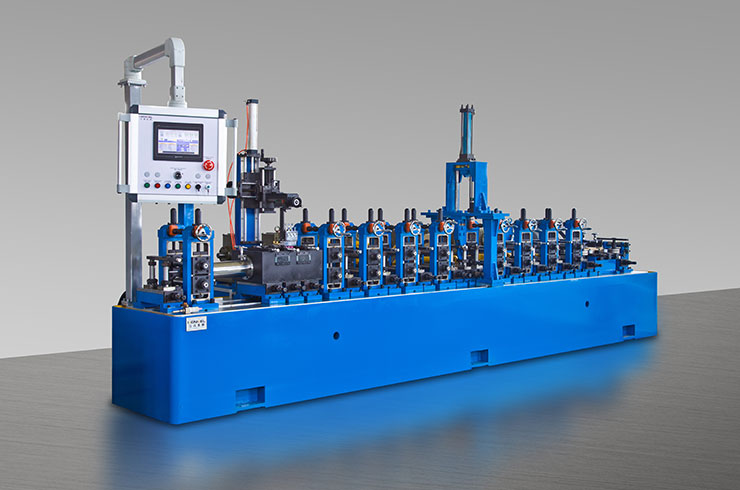

1 High Precision: Shaft Runout ≤ 0.03mm to Ensure Stable Operation of Equipment;

2. Fast Speed: Ensure That the Weld Quality Meets ASME Standard. When 30416 * 0.6mm Is Made, the Speed Can Reach 7M/Min;

3. High Yield: over 98%.

4. the Production Line Data Is Recorded and Saved in All Directions, and the Welding Current, Solid Solution Power, Current, Frequency, Etc. of Each Steel Pipe Can Be Traced Back and Recorded in Real Time.

5. It Has One-Click Start and Stop Function.

6. Perforation Alarm and Automatic Water Stop Function.

Product Introduction

1. Stainless Steel Industrial Pipe Making Machine:

It Is Mainly Used for Industrial Stainless Steel Pipe. Due to the Maturity of Stainless Steel Welded Pipe Technology, It Has Achieved Seamless Pipe in Many Fields. Applied to Heat Exchanger, Fluid Pipe Sanitary Pipe, Automobile Exhaust Pipe, Petroleum

Work, Building Materials, Steel Pipe, Chemical Equipment, Etc,

2. Features of Industrial Pipe Making Machine:

High Precision, Stable Performance, High Finished Product Rate, Full Automation, Simple Operation, Durable, Solid Machine, Continuous Production, High Efficiency, Less Material Waste, Low Production Cost

3. Automated Production Process:

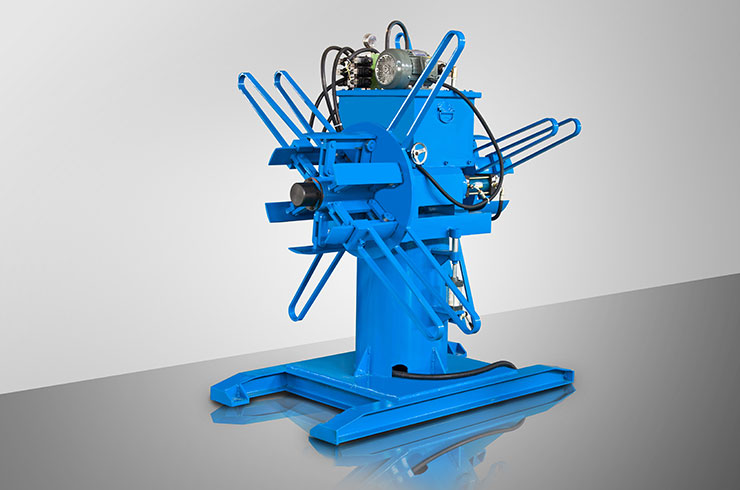

After Uncoiling, Cleaning Device, Feed Guidance, Molding, Welding, Internal Welding Leveling, External Weld Grinding, Shaping and Sizing, Solid Melting Treatment, Final Sizing, Straightening, Flaw Detection, Code Spraying, fixed Ruler, Cut off (Coil)

To Connect Material and Other Continuous Formation Processes, Fine Structure, Easy to Operate

Process Improvement and Innovative Design:

1. We Changed the Unit Table into Sectional Design. after the Welding Is Completed, the Annealing Process Is Added to Remove the Welding Stress to Ensure That the Post-Processing Will Not Deform. After Milling the Plane, Add a Plane Mill to Ensure That the Accuracy of the Machine Is Controlled between 0.01 and 0.02mm.

2. under the Premise That the Machining Accuracy of the Vertical Roller Rack Is Guaranteed, We Have Innovatively Designed a Structure like a Horizontal Rack Type. Bearings Are Installed at Both Ends of the Shaft, U-Shaped Fixed Axis to Ensure That the Shaft Is Not Deformed Vertically, and the Roll Inner Hole and Shaft Are Fixed through Clamping Sets. The Problem of "Eight Characters" Deformation of Vertical Roller Frame Is Solved.

We Provide Customers with Perfect Pipe Production Lines and Product Solutions for Producing High-Standard Welded Pipe Products in Accordance with American Standard ASTM A249,A269,A270,A312 and National Standard Gb151gb12771, HG-20537.1-4, din German Standard and ISO Standard. Share Production Processes with Customers and Provide Comprehensive Services for Factory Planning Solutions

HOME

HOME