Top Benefits of Using a Steel Pipe Hydrostatic Testing Machine

14 January 2026

In industries where steel pipes carry pressure, failure is never just a “quality issue.” It can mean production downtime, safety incidents, rejected shipments, or even legal liability. That’s why hydrostatic testing has remained a standard practice for decades—long before digital sensors and automated inspection systems became popular.

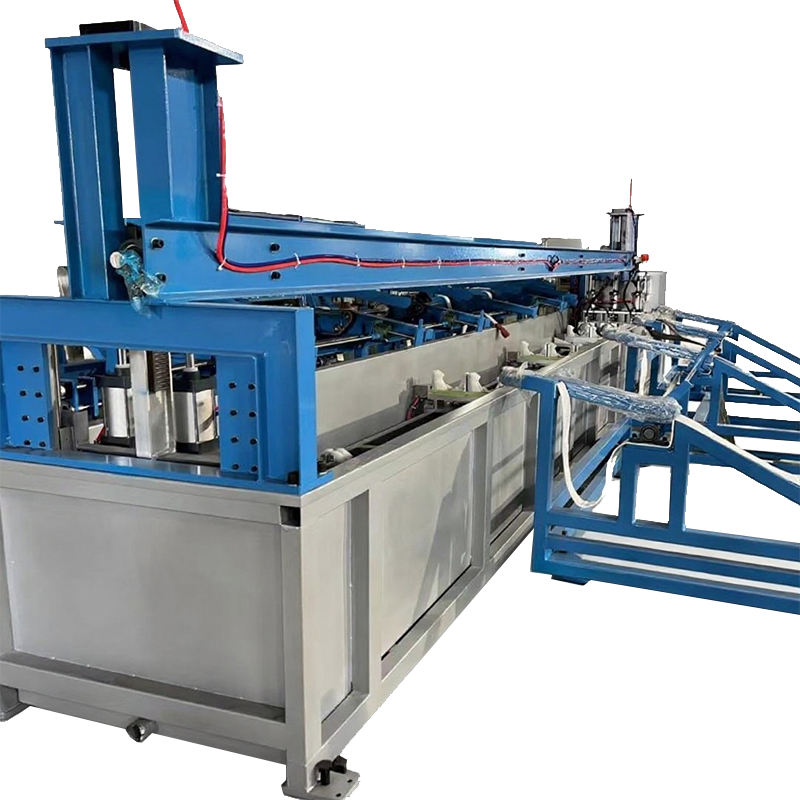

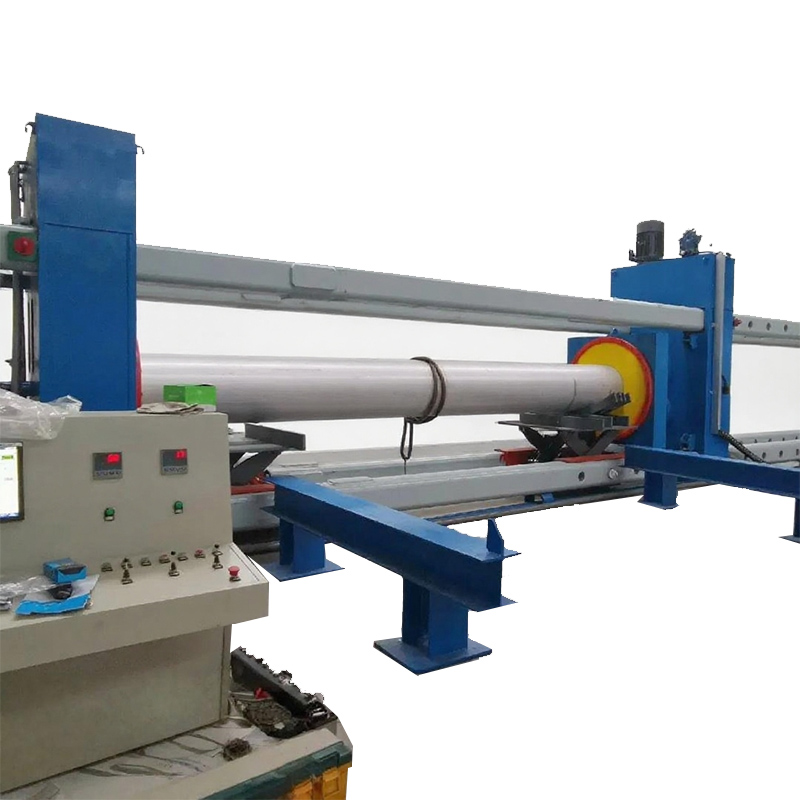

A steel pipe hydrostatic testing machine does one simple thing extremely well: it proves, beyond doubt, that a pipe can safely hold pressure. Below, we break down the real, practical benefits of using hydrostatic testing equipment—and why manufacturers, EPC contractors, and inspectors still rely on it today.

1. Verifies Real Pressure Performance

Visual inspection can catch surface defects. Ultrasonic or eddy current testing can detect internal flaws. But neither can fully answer one critical question:

Will this pipe actually hold pressure in real working conditions?

A steel pipe hydrostatic testing machine fills the pipe with water and pressurizes it to a specified level—often higher than its normal operating pressure. If the pipe survives the test without leakage, deformation, or pressure drop, its integrity is proven in the most direct way possible.

This makes hydrostatic testing especially valuable for:

-

Oil and gas transmission pipes

-

Boiler and pressure piping

-

Fire protection pipelines

-

Structural pipes used under internal pressure

2. Detects Leaks That Other Tests Miss

Some defects are subtle. Micro-cracks, pinholes in weld seams, or poor sealing at pipe ends may not show up during non-pressure inspections. Under hydrostatic pressure, however, these weaknesses reveal themselves immediately.

Typical leak sources found during hydro testing include:

-

Incomplete weld penetration

-

Porosity in ERW seams

-

Material thinning near pipe ends

-

Improper end-cap sealing

Because water is nearly incompressible, even small leaks cause noticeable pressure changes—making detection reliable and repeatable.

3. Improves Compliance with International Standards

Most global standards explicitly require hydrostatic testing for steel pipes. Using a proper steel pipe hydrostatic testing machine helps manufacturers and exporters meet compliance requirements without ambiguity.

Common standards that specify hydrostatic testing include:

| Standard | Industry | Hydro Test Requirement |

|---|---|---|

| ASTM A106 / A53 | Carbon steel pipes | Mandatory pressure test |

| API 5L | Line pipe | Hydrostatic or approved alternative |

| EN 10216 / 10217 | Pressure pipes | Required |

| ISO 15649 | Industrial piping | Required |

| ASME B31 | Process piping | Pressure testing required |

For exporters, this is critical. Many buyers will not accept pipes without documented hydro test results.

4. Reduces Rejection Rates and Costly Returns

Shipping non-conforming steel pipes is expensive—especially in overseas projects. One failed pressure test at the customer’s site can lead to:

-

Full batch rejection

-

On-site retesting costs

-

Delayed project schedules

-

Damage to supplier credibility

Testing pipes in-house with a steel pipe hydrostatic testing machine allows manufacturers to identify weak pipes early, before packaging and shipment. The cost of testing is minor compared to the cost of returns or disputes.

5. Enhances Safety for Workers and End Users

Pressure-related failures are among the most dangerous incidents in piping systems. A burst pipe doesn’t just fail—it releases energy violently.

Hydrostatic testing improves safety at two levels:

-

Factory level – Operators work with water instead of compressed gas, significantly reducing risk during testing.

-

End-user level – Only pressure-proven pipes reach installation sites, reducing long-term operational risks.

This is one reason hydrostatic testing is preferred over pneumatic testing whenever possible.

6. Works for Both Seamless and Welded Steel Pipes

Modern steel pipe hydrostatic testing machines are highly adaptable. With adjustable pressure ranges and flexible sealing systems, they can test:

-

Seamless carbon steel pipes

-

ERW and LSAW welded pipes

-

Stainless steel pipes

-

Alloy steel pressure pipes

Pipe diameters, lengths, and wall thicknesses can be adjusted depending on the machine configuration, making hydro testing suitable for mixed production lines.

7. Provides Clear, Recordable Test Results

Unlike subjective inspections, hydrostatic testing produces measurable data:

-

Test pressure

-

Hold time

-

Pressure drop (if any)

-

Pass / fail result

Many modern machines can log this data automatically, making it easy to generate inspection reports for customers, auditors, or certification bodies.

Over time, consistent hydro test results help build trust, reduce inspection disputes, and strengthen long-term partnerships—especially in competitive export markets.

Despite advances in non-destructive testing, the steel pipe hydrostatic testing machine remains one of the most trusted tools in pipe quality assurance. It doesn’t rely on assumptions or indirect signals. It applies pressure and lets physics decide.

For manufacturers focused on safety, compliance, and long-term reputation, hydrostatic testing is not an optional step—it’s a smart investment.

HOME

HOME