Pipe pressure testing machine

pipe pressure testing machine

Pipe pressure testing machine Unit Description:

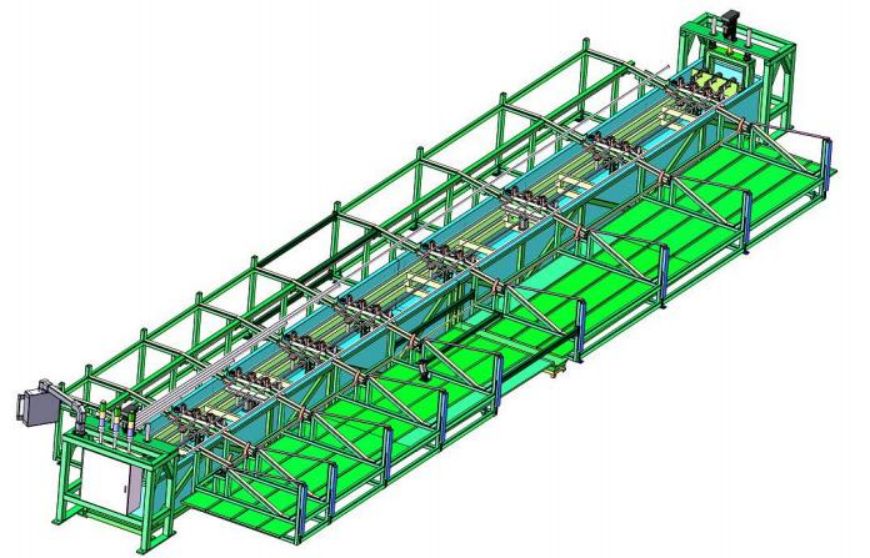

Pipe pressure testing machine This machine is primarily used for underwater airtightness pressure testing of metal pipes. The pressure tester utilizes a transverse conveyor mechanism for loading and unloading. Multiple pipes can be tested during each cycle. The pressure test process is monitored and controlled by an industrial computer + PLC. It features a rational structural design, advanced and mature technology, stable system operation, easy operation and maintenance, strong continuous operation stability, and high inspection efficiency.

1. Pipe pressure testing machine Unit Operation Overview:

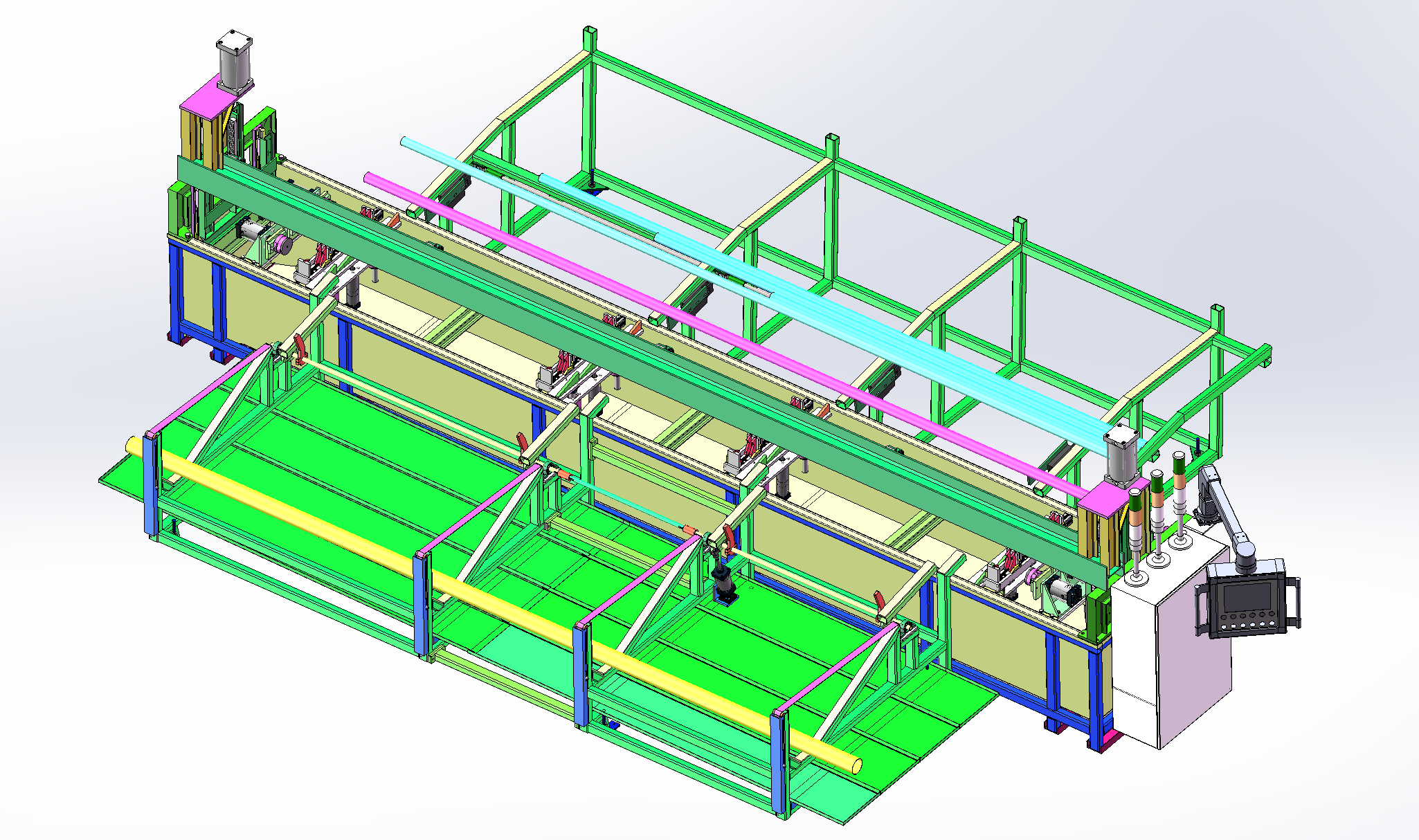

This equipment features a multi-station design and uses compressed air as the testing medium. Tubes are inflated and then lowered into a testing water tank. Controlled by an intelligent system, multiple tubes can be tested simultaneously, with simultaneous loading and unloading, saving time. The equipment includes storage, discharge, loading, automatic inspection, automatic sorting, and automatic, non-destructive unloading. Its automatic sorting function allows for unattended operation once fully operational, allowing one person to operate multiple units, reducing labor intensity and costs.

2. Pipe pressure testing machine Unit Workflow:

Discharging → Automatic loading → Tube clamping → Sealing (sealing both ends of the fitting) → Submersion (inflating) → Inspection → Rejection

↗Qualified tubes → Finished product storage rack

→ Automatic unloading → Automatic sorting

↘Rejected parts → Rejected storage

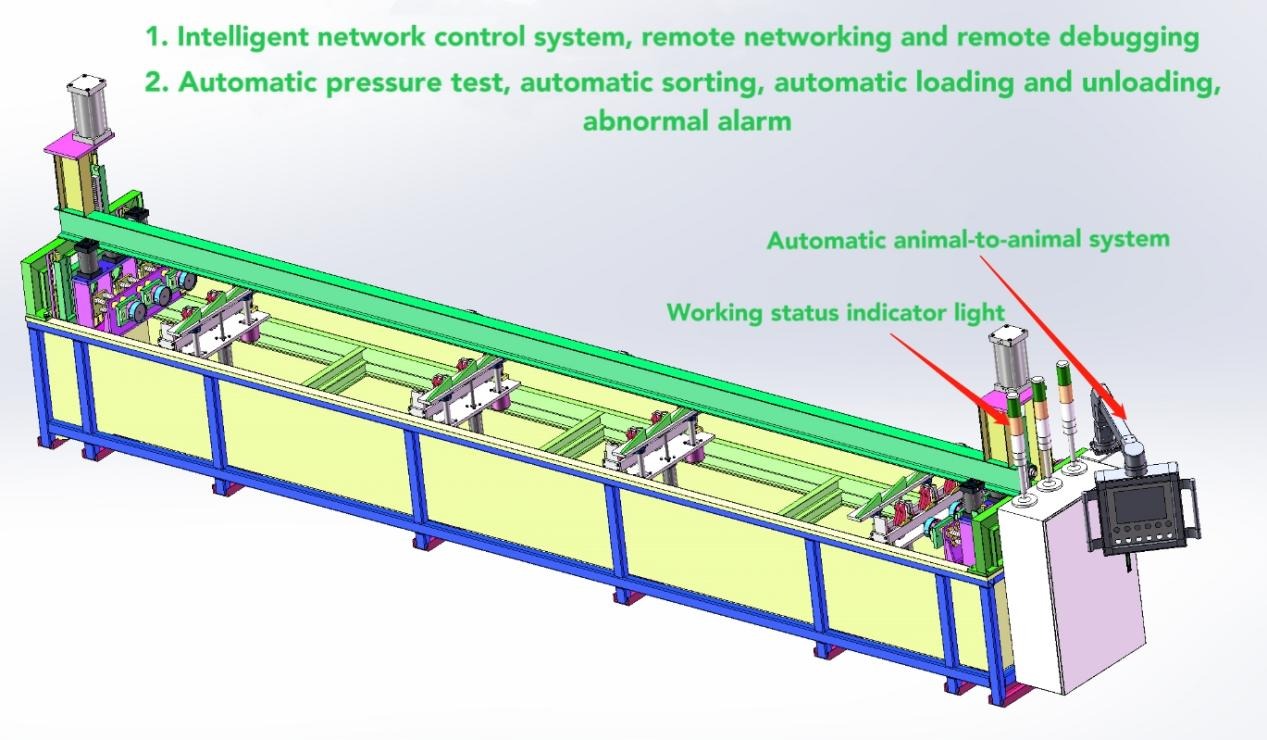

Pipe pressure testing machine Intelligent Control System: The system utilizes PLC-programmed intelligent control, a human-machine interface, and touchscreen input and adjustment. It features automatic control, automatic pressure testing, automatic memory sorting, and automatic alarms. During testing, it automatically determines the conformity of products at each station based on the holding pressure at each station and stores the information. When unqualified products are unloaded at a station, the automatic storage rack is automatically linked to sort them into the unqualified storage bin. If unqualified products appear three times consecutively in the same bin, the system automatically shuts down and alarms, reminding the operator to check for leaks and replacement of the sealing head. The system also offers remote maintenance and monitoring capabilities, automatically generates reports, and interfaces with production management systems.

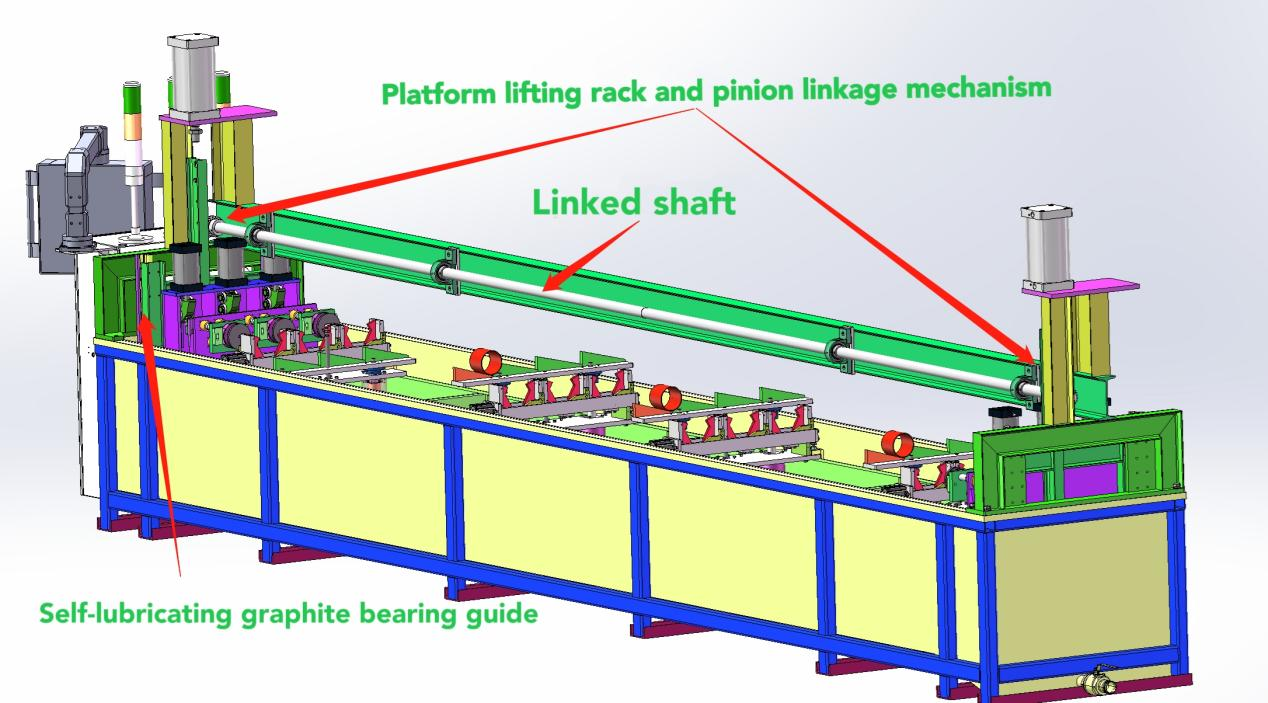

Pipe pressure testing machine Automatic sinking device: dual pneumatic sinking mechanism design, composed of two groups of cylinders + air source detection system, rotating shaft + gear rack synchronous design to ensure the synchronization of sinking on both sides, the cylinder adopts double guide rod chrome rod + graphite copper sleeve guide, the back of the head is pressurized and inflated for inspection and sinking at the same time, after sinking, the pressure is maintained for a certain time and the material is automatically floated up and withdrawn (the pressure holding time can be adjusted according to demand), floating and withdrawing are carried out simultaneously, shortening the inspection process cycle time.

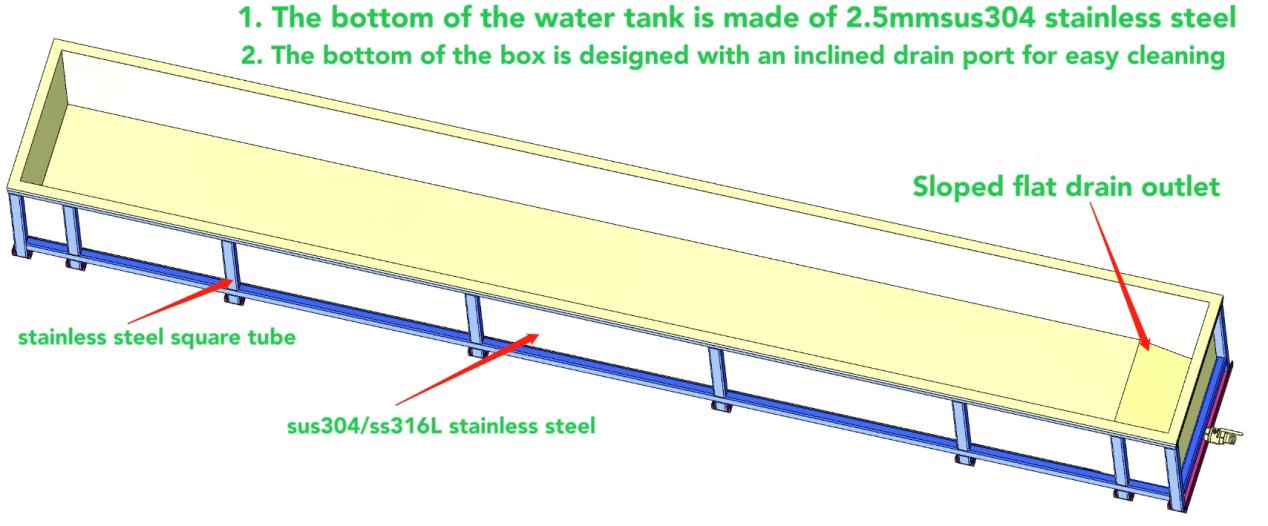

Pipe pressure testing machine Test Tank: The tank is constructed from a 304 stainless steel test tank frame, welded from 2.4mm thick 304 stainless steel plates and section steel. To prevent rust and perforation from long-term water storage, the tank is designed with inlet and outlet ports, and a sloped bottom for easy cleaning, replacement, and discharge of test water.

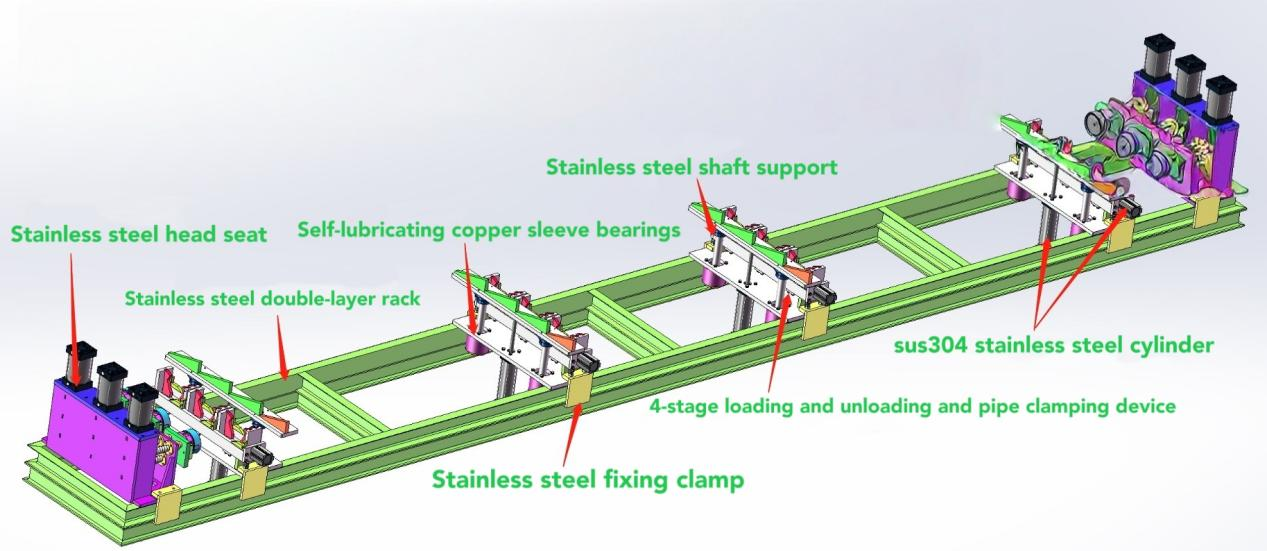

Pipe pressure testing machine The inspection platform features a double-layer load-bearing beam structure constructed from double layers of national standard SUS304 stainless steel H-steel and stainless steel I-beams to prevent rust, bending, and deformation. The platform incorporates four components: an automatic loading and unloading mechanism, an automatic pipe clamping device, an automatic capping device, and an automatic sinking inspection device. These devices utilize a segmented compression design, allowing the position of the loading, clamping, and capping devices to be adjusted to accommodate pipes of varying lengths during testing.

Pipe pressure testing machine Automatic Loading and Clamping Unit Overview:

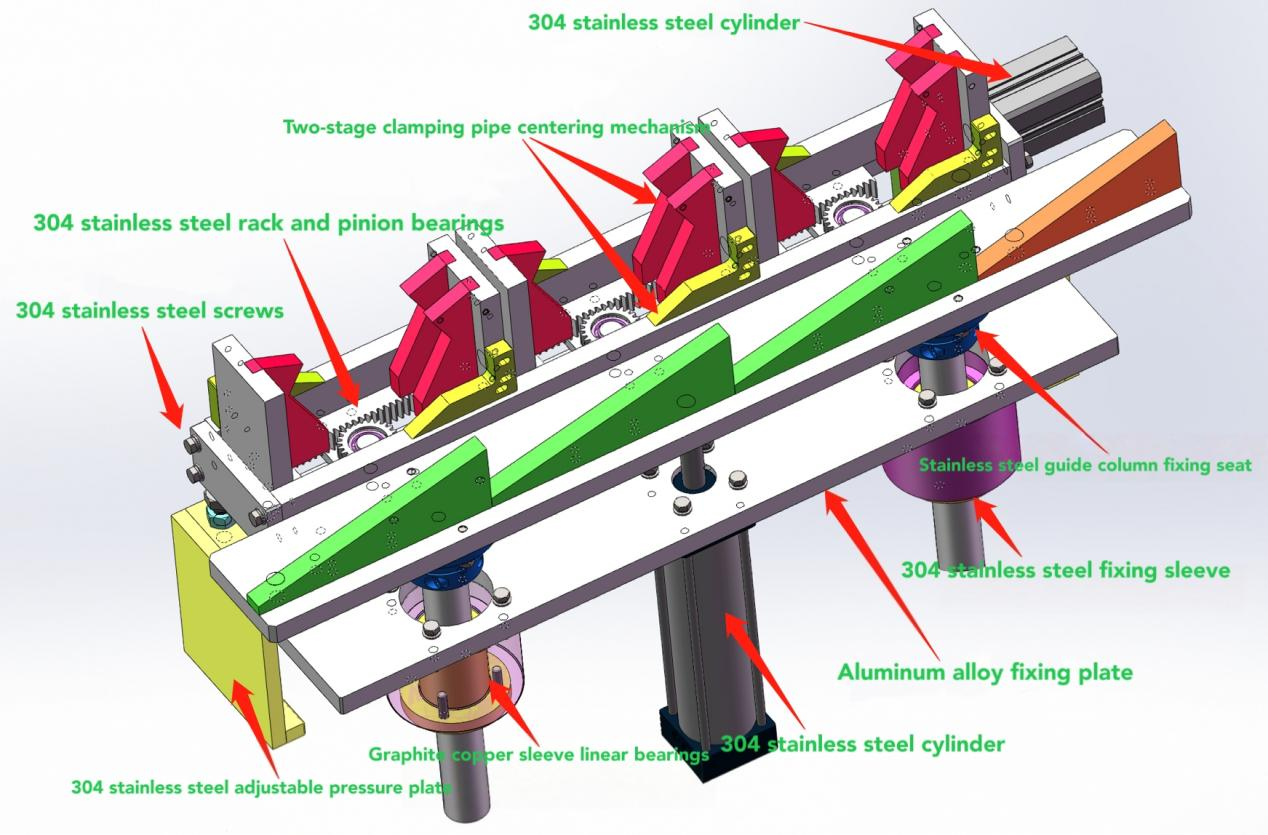

1. The automatic loading and unloading mechanism consists of four sets of 304 stainless steel cylinders and four sets of pipe-pushing triangles. They utilize dual chrome-plated guide rods and 304 stainless steel linear bearings to minimize the risk of the guide rods rusting and jamming. The pipe-pushing triangles are constructed from rubber sheet to prevent scratching of the pipe surface.

2. The pipe-pushing mechanism consists of four sets of cylinders and four sets of stainless steel gear-toothed mounting bases. The clamping plate and clamp design allow for flexible adjustment to accommodate varying pipe lengths. The V-shaped clamping plate automatically centers the pipe after clamping, eliminating the need for adjustment when switching between larger and smaller pipe sizes. The clamping plate is constructed from rubber sheet to prevent scratching of the pipe surface.

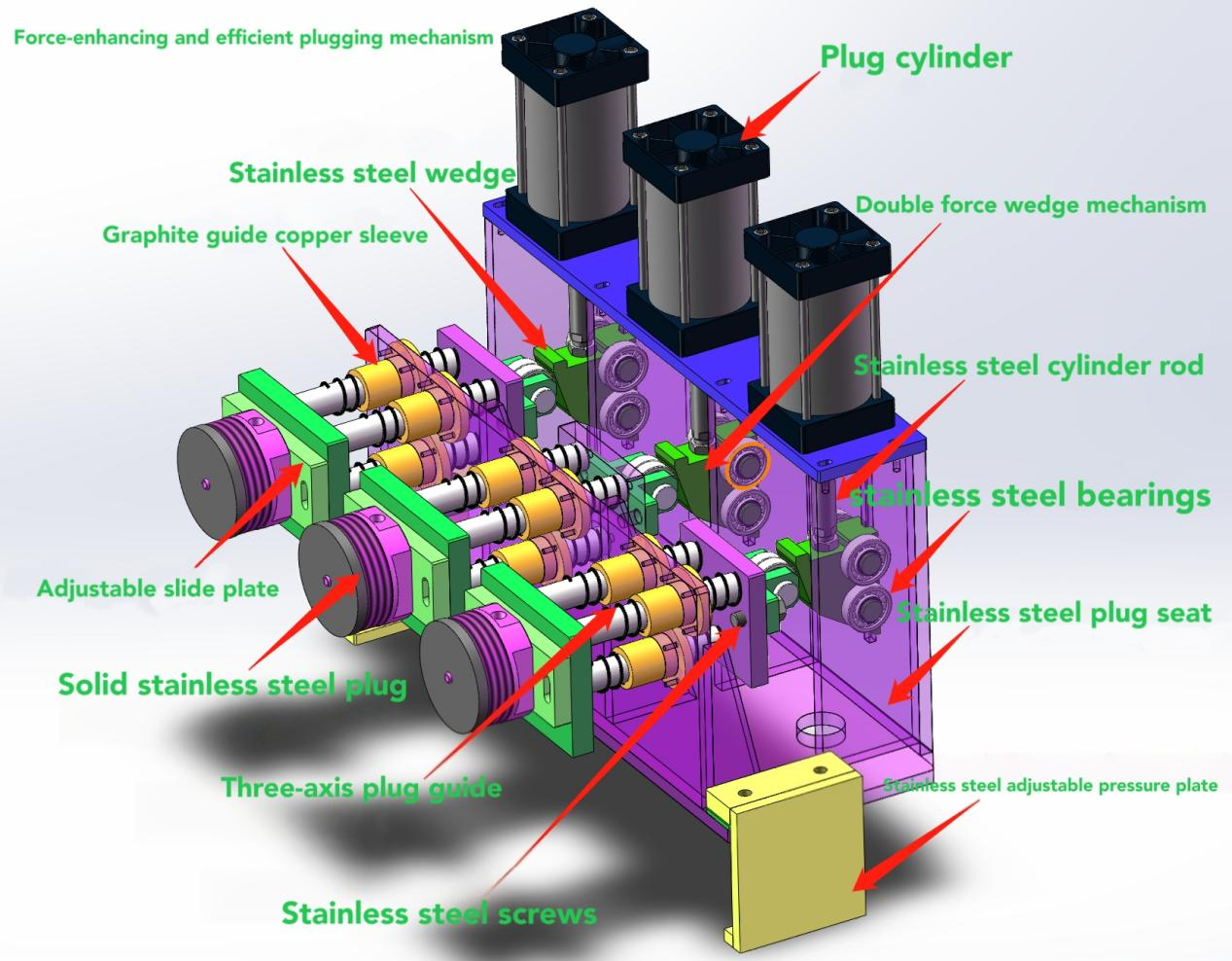

Pipe pressure testing machine Automatic plugging device: The assembly consists of a plugging mechanism, drive mechanism, guide mechanism, and sealing mechanism. The left and right sides feature stainless steel mounting brackets and pneumatic plugging devices, one fixed and the other adjustable to accommodate varying pipe lengths.

1. The plug utilizes a multiplier wedge-shaped force-amplifying design, increasing cylinder plug pressure without increasing the cylinder diameter. This achieves a sealing effect while also reducing cylinder inflation time, extending cylinder life, and improving pressure testing efficiency.

2. The plug retractable mechanism utilizes a three-guide rod + graphite copper sleeve design, offering stability, rust resistance, and durability.

3. The plug sealing gasket utilizes a conveyor belt design, which offers superior sealing performance and a longer service life compared to conventional silicone gaskets.

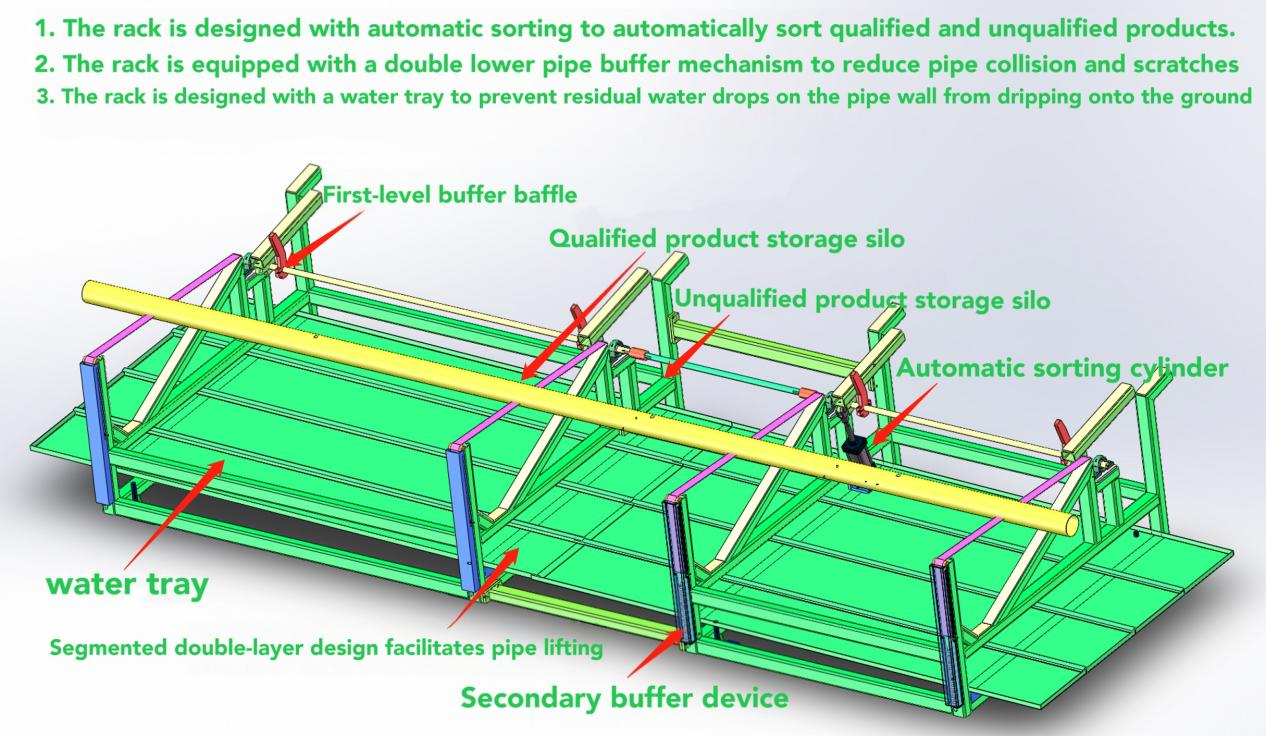

Pipe pressure testing machine Automatic sorting and unloading rack: welded with national standard steel, with independent unloading device, 4-section discharge platform, compatible with 2.4m-6m pipes, with two storage positions for qualified products and unqualified products. The storage switching of each position is controlled by the automatic sorting system to control the swing arm for sorting and switching. The storage part has a double-layer design with a water collection tray. After the pressure test, the water droplets remaining on the pipe wall drip into the water collection tray for unified collection. The middle section is left empty for convenient pipe hanging.

HOME

HOME