How a Hydrostatic Testing Machine Ensures Leak-Free Pipe Operations

26 August 2025

No matter the scale of piping infrastructure—be it in oil, water, manufacturing, or chemical plants—leaks are a costly and dangerous threat. That’s where the Hydrostatic Testing Machine comes in. With a simple yet powerful process of pressurizing pipes using water, this machine gives operators unmatched confidence in system integrity long before operations begin.

1. Detects Leaks and Weaknesses Before Operations Begin

Hydrostatic testing involves filling the pipeline with a liquid—typically water—and applying pressure that exceeds normal operating levels. This method brings any hidden leaks or material faults into clear view by monitoring for pressure drops or visible seepage.

2. Mimics Real-World Conditions Without Risk

Unlike gas-based testing, hydrostatic testing mimics actual operating conditions because pipelines usually carry liquids. Being an incompressible medium, water enables precise detection of even the tiniest leaks without the danger of explosive decompression.

3. Complies with Industry Standards and Enhances Safety

Procedures like ASME B31.3 require pressure testing before pipelines go live. A Hydrostatic Testing Machine ensures compliance and proves that equipment can handle the expected stress—strengthening safety and regulatory adherence.

4. Reduces Risk and Operational Costs

Identifying defects early through hydrostatic tests prevents potential downtime, expensive repairs, and environmental hazards. It’s an investment that saves money while safeguarding operations.

5. Strengthens Quality Control and Reliability

As a non-destructive test, hydrostatic testing is a trusted quality-control measure. It generates confidence in pipes, vessels, and valves—ensuring they perform flawlessly under pressure.

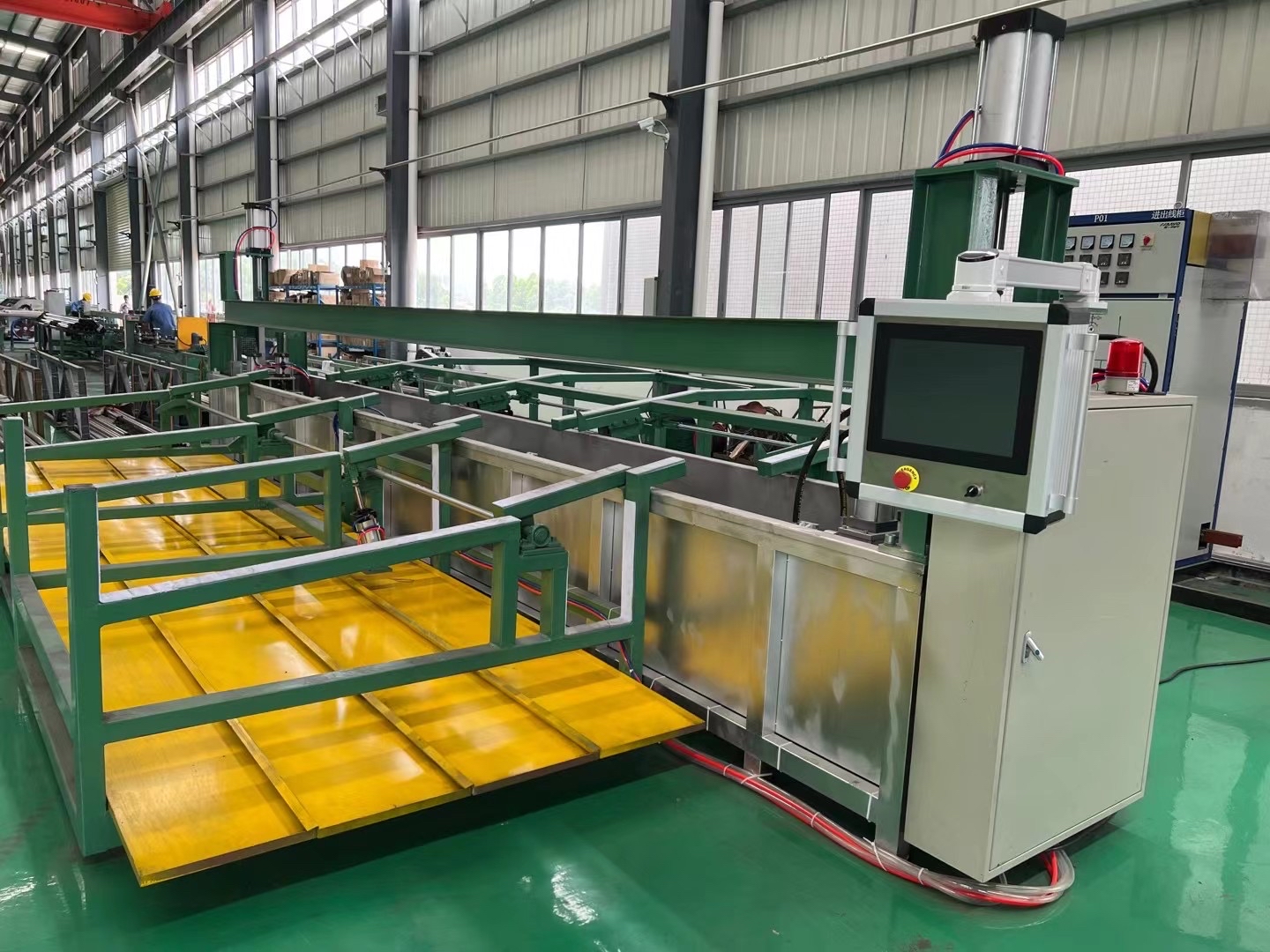

Real-World Workflow in Practice

Here’s how a Hydrostatic Testing Machine typically operates in a factory setting:

-

Preparation & Filling: Pipes are isolated, cleansed, then filled with de-aerated water—sometimes with dye to highlight leaks.

-

Pressure Ramp-Up: Pressure is raised to 1.3–1.5× design pressure.

-

Monitoring: Pressure gauges and data loggers check for drops or visual leaks.

-

Depressurization & Drainage: If no leaks appear, the system is safely depressurized, drained, and prepped for service.

Summary of Benefits

|

Benefit |

Impact on Pipe Operations |

|

Early Leak Detection |

Prevents failures before operational use |

|

Accurate Simulation |

Mirrors real conditions safely without explosion risk |

|

Regulatory Compliance |

Meets ASME, API, and other required standards |

|

Cost & Risk Reduction |

Lowers repair costs and avoids environmental incidents |

|

Quality Assurance |

Validates system integrity for reliable operation |

Buying Tips: Choosing the Right Hydrostatic Testing Machine

-

Pressure Capacity: Ensure it offers at least 1.3–1.5× your pipeline’s design pressure.

-

Safety Features: Requires accurate gauges, safety valves, and emergency controls.

-

Automation & Data Capture: PLC systems and data loggers are ideal for tracking test parameters.

-

Water Quality Control: Use clean or treated water to prevent corrosion during and after tests.

Conclusion

Leak-free piping isn’t a luxury—it’s a necessity. A Hydrostatic Testing Machine offers comprehensive, safe, and standardized validation of pipeline integrity. With early leak detection, compliance certainty, and operational resilience, it’s a foundational asset for quality-focused manufacturers.

HOME

HOME